GRIP GRIP on safe human-machine interaction

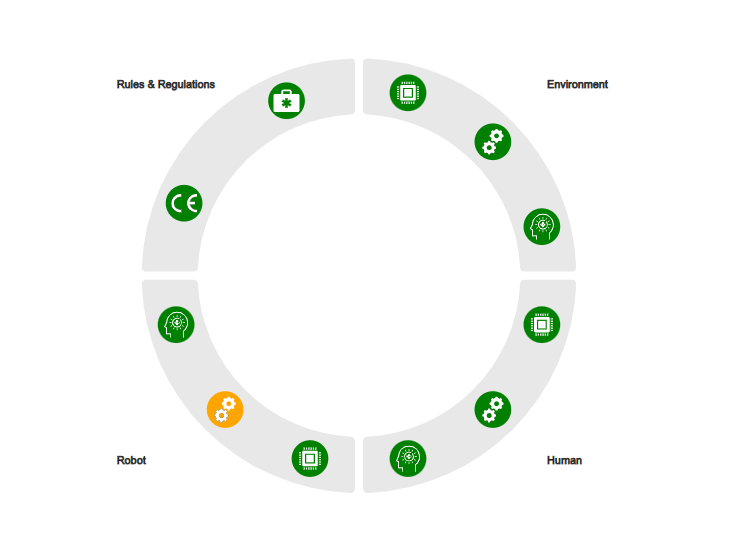

GRIP (Guarding Robot Interaction Performance) is an RI&E that is specifically aimed at human-machine interaction and various requirements from the Machinery Regulation. Various aspects of safety risks and control measures are examined via a structured questionnaire. This involves looking at technical factors, the human factor and the environment factor.

Safety risks in the workplace change as a result of technological developments and changes in the labor market. Robotics, AI (artificial intelligence) and machine learning (ML) can identify and help prevent risks on the one hand, but pose new security risks themselves on the other hand. To ensure occupational and process safety, these risks must be inventoried and limited as much as possible. GRIP is a tool that has been specially developed for this.

GRIP on safe human-machine interaction

GRIP (Guarding Robot Interaction Performance) is an RI&E that is specifically aimed at human-machine interaction and various requirements from the Machinery Regulation. Various aspects of safety risks and control measures are examined via a structured questionnaire. This involves looking at technical factors, the human factor and the environment factor.

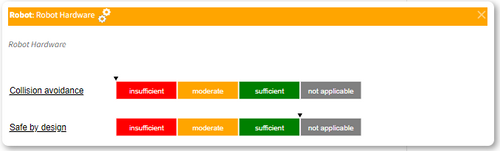

A digital visualization (profile wheel) provides insight into the risks. A traffic light model clearly shows in which areas (additional) measures need to be taken:

- OK (green)

- certain aspects not OK (orange)

- not OK (red)

Risk assessment for robots and cobots

The use of intelligent technologies such as robots and cobots (robots that collaborate) entail new safety risks. A good risk assessment for human-machine interactions is important even before the purchase and implementation of robots and cobots:

- Inventory the diversity of production processes within/between companies;

- Make a well-founded assessment of whether, and if so which, cobots fit into your business process;

- Inventory safety risks of human-machine interactions;

- Think about ensuring safety, efficiency and sustainable employability.

GRIP is based on clear guidelines and requirements for safe Human Robot Interaction (HRI) and is therefore ahead of the recent requirements of the Machinery Regulation in this area. It provides tailor-made solutions for the specific business situation and focuses on robots, people and the environment. GRIP is data-driven.

Benefits of GRIP for human-machine interaction

- Better understanding of cobot safety

- Insight into how safe your (potentiel) cobot is in terms of interaction with employees

- Insight into what the right management resources are to invest in

- Direct connection possible with Bowtie-software

Literatuur

Getting started with GRIP?

GRIP can be directly applied and is free of charge. To get access to GRIP, please send an email to support.diamonds@tno.nl.

We are also looking for parties to improve GRIP in practice with more data. The objective is to make GRIP suitable for real-time monitoring of the risks and the quality of the control measures taken over time. We are looking for partners with a cobot or who intend to purchase a cobot or an entire production line of cobots. Our experts work with you te make a good inventory of the possibilities. If you are interested, please send an email to arbeidsveiligheid@tno.nl for more details. Please include your company name.

Deze webpagina is ook beschikbaar in het Nederlands.